Resources

Metallurgical Lab

| Test Description | Specification (ASTM & Other) |

| Rockwell Hardness Testing A, B, C, N, T | ASTM E18, F606, F606M, SAE J429 |

| Brinell Hardness Testing – 87.5, 500, 750, 3000Kg | ASTM E10 |

| Microhardness (Knoop & Vickers) 100, 500 HK, 100, 300, 500, 1000 HV | ASTM E384, F606, F606M |

| Vickers Hardness Testing HV 5000, HV 1000 | ASTM E92, ISO 6507-1 |

| Jominy Hardenability | ASTM A255, SAE J406; ISO 642; CAT 1E0024 |

| Specimen Preparation | ASTM E3 |

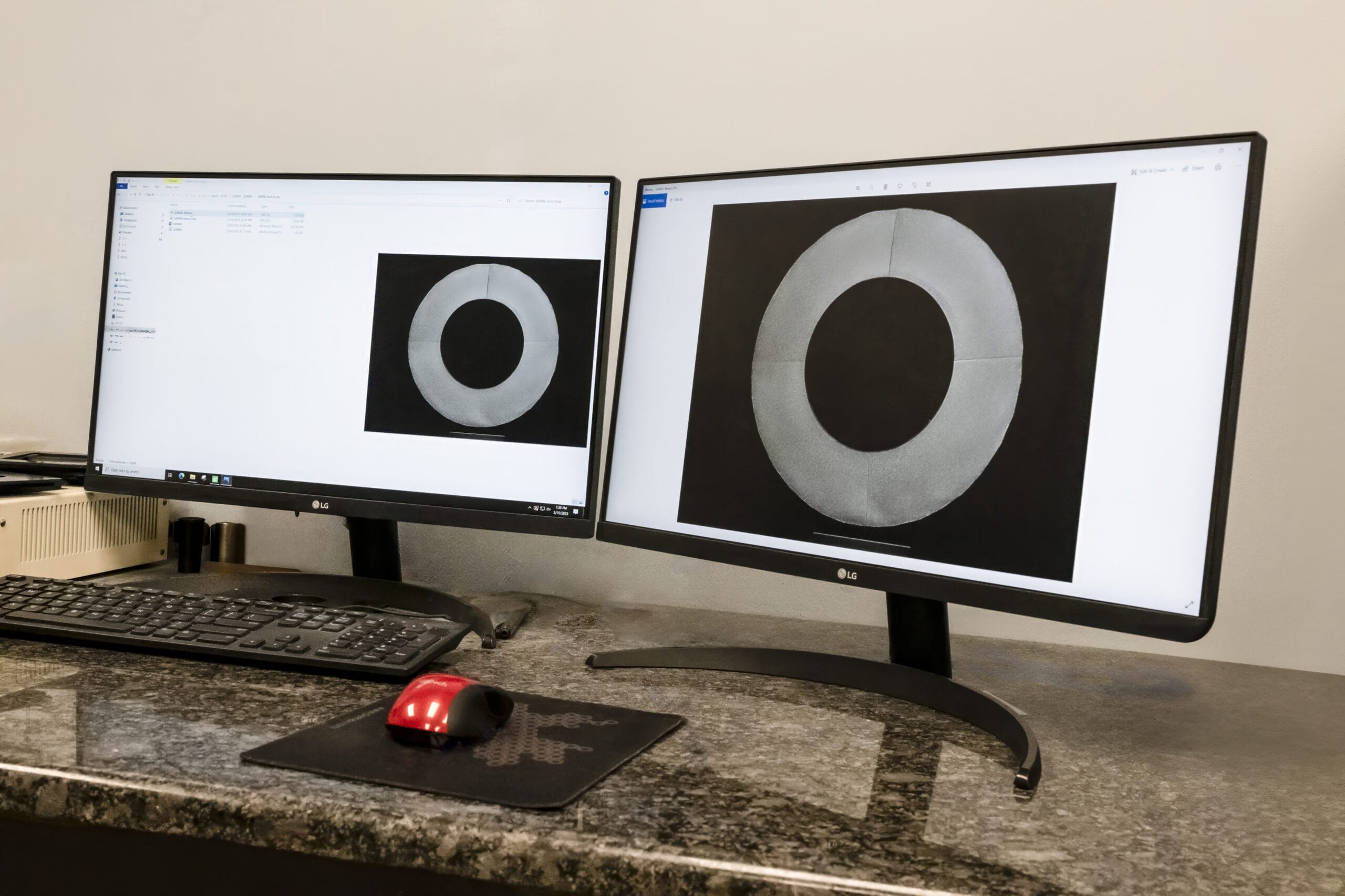

| Macroetch Testing | ASTM E381, ASTM A604 |

| Microetching Metals and Alloys | ASTM E407 |

| Grain Size Exam | ASTM E112, E1181, ASTM E930 |

| Micro-Cleanliness Rating | ASTM E45 (Method A, C, D, E), ISO 4967 (Method A and B); DIN 50602 (Method M & K); JIS G 0555 |

| Case Depth | SAE J423 |

| Discontinuity Exam | ASTM A574, F788, F812, ISO 898-1 |

| Decarburization Exam | ASTM E1077, F2328, J419 |

| Volume Fraction by Point Count | ASTM E562, SAE AMS 2315 |

| Graphite Microstructure | ASTM A247 |

| SEM/EDS | ASTM B748, E766 |

| Salt Spray (Fog) | ASTM B117, ISO 9227 |

| Intergranular Attack in Austenitic (SS) | ASTM A262 (Practice A, C & E), ISO 3651-2 Method A |

| Detrimental Intermetallic Phases in Duplex Stainless Steels | ASTM A923 |

| Inclusion or Second-Phase Content by Automatic Image Analysis | ASTM E1245 |

| Measurements by Optical Microscope Examination | ASTM B487 |

| Coating Weight (Zn) | ASTM A90 |

| Bend Testing | ASTM A370 Sec. 15, ASTM E290 Guided Bend, Semi- Guided Bend; AWS B4.0 (Part A) |

| Charpy Impact Testing (Type A) | ASTM E23; ISO 148-1; JIS Z 2202, JIS Z 2242 |

| Proof (Internal & External Threads) | ASTM F606/606M; SAE J429, J1199 |

| Surface Roughness | ASME B46.1 |

| Tensile Testing (Axial & Wedge) | ASTM B557, E8/E8M, F606/606M; SAE J429, J995, J1199; ISO 6892-1 |

| Weld Procedure and Weld Operator Qualification | AWS B4.0 (Part A-D): D1.1, D1.2, D1.5, D1.6; ASME Section IX; NAVSEA S9074-AQ-GIB-010/248 |

| Optical Emission Spectroscopy (OES): | |

| Steel: Al, As, B, Bi, C, Ca, Co, Cr, Cu, Mn, Mo, N, Nb, Ni, P, Pb, S, Sb, Si, Sn, Ta, Ti, V, W, Zr | ASTM E415, A751 |

| Stainless Steel: Al, B, C, Ca, Ce, Co, Cr, Cu, Fe, Mn, Mo, N, Nb, Ni, P, Pb, S, Si, Sn, Ta, Ti, V, W, Zr | ASTM E1086, A751 |

| Aluminum: Ag, Al, B, Be, Bi, Ca, Cd, Cr, Co, Cu, Fe, Mg, Mn, Na, Ni, Pb, Sb, Si, Sn, Sr, Ti, V, Zn, Zr | ASTM E1251 |

| Titanium: Al, Bi, C, Cr, Cu, Fe, H, Mn, Mo, N, Ni, O, Pb, S, Sn, V, Ti, Se, Zr | ASTM E2994 |

| Copper: Ag, Al, As, Be, Bi, C, Cd, Co, Cr, Cu, Fe, Mg, Mn, Ni, P, Pb, Se, Sb, Si, Sn, S, Te, Zn, Zr | EN 15079 |

| Nickel: Al, B, C, Co, Cr, Cu, Fe, Mg, Mn, Mo, N, Nb, Ni, P, Pb, S, Si, Sn, Ta, Ti, V, W, Zr | ASTM E3047 |

| Cast Iron: B, C, Ca, Ce, Cr, Co, Cu, Mg, Mn, Mo, N, Nb, Ni, P, Pb, Si, S, Sn, Ta, Ti, V, W, Zr | ASTM E1999, A751 |

| High Mn Steel: Al, C, Cr, Cu, Mn, Mo, N, Ni, P, S, Si | ASTM E2209, A751 |

| Combustion/Absorption Analysis LECO – C, N, O, S | ASTM E1019, E1409, E1941 |

| Density of Compacted or Sintered Powder Metallurgy (PM) Products Using Archimedes Principle | ASTM B962, B963, B311 |

| Fusion Analysis – Titanium & Steel & Aluminum LECO – Hydrogen | ASTM E1447, E2792 |

| Graphitic Carbon – Cast Iron | ASTM E351 |

| Hexavalent Chrome | ISO 3613; GMW 3034; DX 900359 |

| Inductively Coupled Plasma (ICP) | ASTM E1479, E2371 |